01 November, 2015

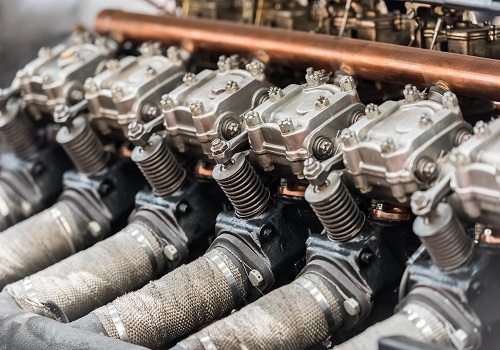

Spark ignition engines can benefit from butanol additives.

© 2015 Alamy

An improved formula for a gasoline additive has been developed by researchers from KAUST and oil company Saudi Aramco. The new mixture of butanol additives reduces engine knocking, a major obstacle to improved engine performance.

“Engine knock is a limiting factor particularly when it comes to increasing the efficiency of engines through downsizing or turbocharging,” said Aamir Farooq from KAUST’s Clean Combustion Research Center.

Knocking can be reduced by introducing additives to the gasoline, which suppress disruptive ignition events. However, many existing additives are hazardous. They typically dissolve in water, which can harm the environmental and, if there is a gasoline leak, may threaten human health.

Ethanol is an environmentally-friendly replacement additive obtained from biological materials, and it is widely used as a biofuel. Ethanol does, however, mix with water, hampering the possibility to transport gasoline through pipelines over longer distances.

Butanol compounds are good alternatives as they have a similar chemical structure to ethanol, but they have more carbon atoms per molecule and boast a higher energy density per molecule. Another advantage is that they mix less with water, making the transport through oil pipelines more feasible.

The combined practical and theoretical results demonstrate that the butanol mixture improves the performance of gasoline engines at typical operating temperatures, assisted by the interaction of the additives with the primary fuel in the engine.

Improved and more environmentally friendly gasoline mixtures might soon be a reality and would enable the development of higher-performing engines.

Click here to read this news item on KAUST Discovery where it was originally published.