A major thrust of research is simulating the combustion chemistry of transportation fuels. We develop fundamental chemical kinetic models that can be used to simulate fuel combustion and pollutant formation in energy systems. Engine designers then implement these chemical kinetic models in computational fluid dynamic (CFD) simulations to achieve various performance targets.

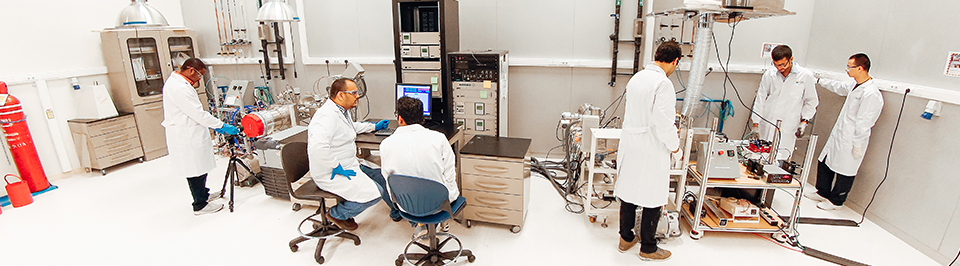

Understanding kinetics of chemical reactions occurring in combustion systems requires experimental data on spatial and temporal species profiles. This includes concentrations of reactants, products, stable and reactive intermediate species. Research at the CPC lab endeavors to study the combustion chemistry of gaseous and liquid fuels, through well-defined experiments (0-D, 1-D, etc.) and advanced diagnostics (e.g., mass spectrometry and optical).

The Electron Impact Ionisation–Molecular Beam Mass Spectrometry (EI-MBMS) sampling system is used for identification and quantification of reactants, intermediates, and products. The sampling of the reactor contents is done by a quartz nozzle and a skimmer, which allows for the formation of a molecular beam.

Laser diagnostics are widely used to study combustion kinetics, due to its high resolution and high accuracy. In the CPC lab, we use a Ti:S laser absorption technique that provides non-intrusive measurements of radicals in JSR oxidation. Experimental data are used for validating combustion kinetic mechanisms.