The High Pressure Combustion Laboratory attempts to simulate fundamental combustion behavior (e.g., autoignition,

The High Pressure Combustion Laboratory attempts to simulate fundamental combustion behavior (e.g., autoignition,  thermo-acoustic instability) and pollutant formation (NOx and soot) kinetics at pressures relevant to internal combustion engines and gas turbines (both aircraft and power generation. Most practical hardware operates at elevated pressures to increase thermodynamic efficiency and power density. We approach these conditions.

thermo-acoustic instability) and pollutant formation (NOx and soot) kinetics at pressures relevant to internal combustion engines and gas turbines (both aircraft and power generation. Most practical hardware operates at elevated pressures to increase thermodynamic efficiency and power density. We approach these conditions.

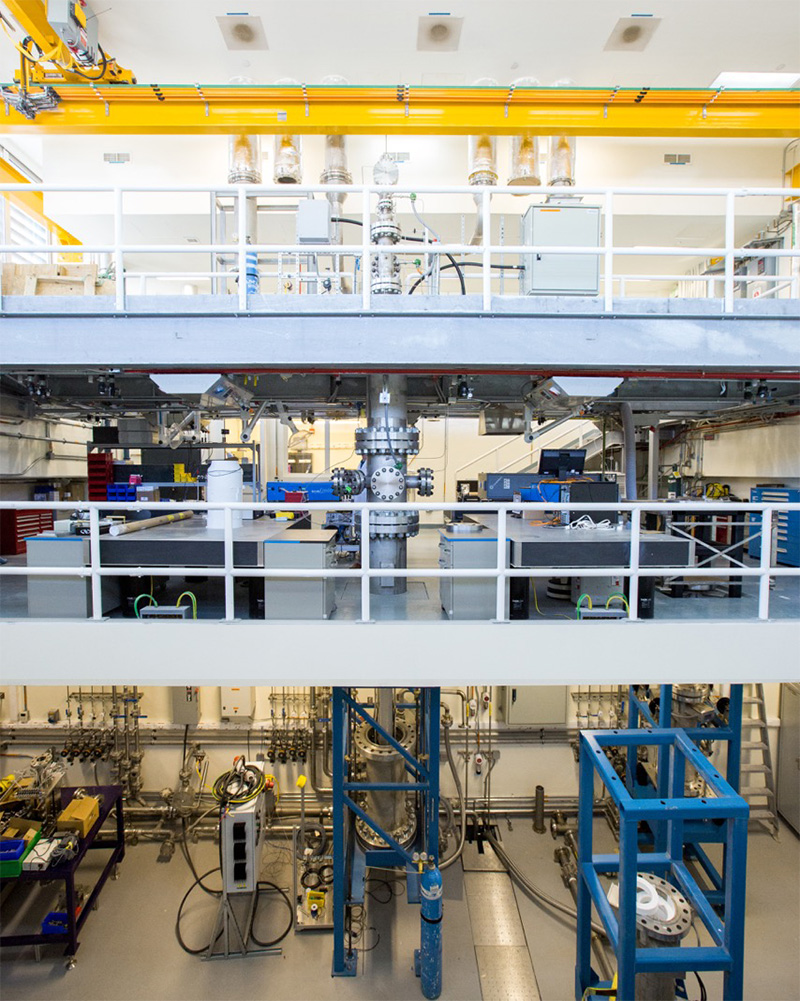

There is no facility in the world with this combination of high pressure, high gas mass flow and high end optical spectroscopy

This facility is a framework of infrastructure for fundamental high pressure investigations; experiments are plug and play modules

The safety infrastructure is Aramco industrial standard with maximum academic level flexibility

Thermodynamic efficiency of jets and turbines require continually moving towards higher and higher pressure combustion. Our lab infrastructure approaches these levels.

Combustion kinetics have non-linear pressure dependencies and are rich in academic fundamental studies

The lab is designed to be large scale for approximation to real world interests (very high Reynolds number flames)

Exceptional optical access for diagnostics; chemical species, soot formation, temperature, and heat release rate at high pressure

High pressures (45 bar) and sustainable mass flux (0.16kg/s heated, 0.5 kg/s unheated), real fuels at relevant pressures,

Five different experiments are in place using the combustion infrastructure

Fundamental to the operation of this laboratory is an infrastructure capable of delivering sustained high volumes of air at high pressure to points within the lab. Every experiment in the lab taps into this air source through the pipe network and valve system.

A high pressure combustion duct (45 bar) is used to contain high Reynolds number flames for fundamental turbulence-chemistry interaction studies as well as soot formation. The apparatus is 8 meters tall and weighs >10,000 lbs).