08 July, 2018

|  |

Assistant Professor Deanna Lacoste and her student Francesco Di Sabatino discuss the advantages of the setup.

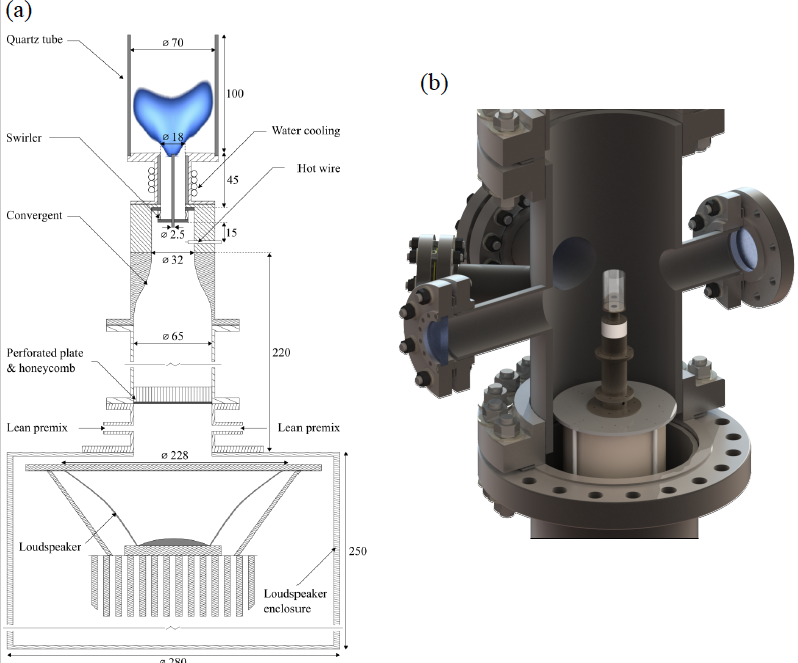

a) A loudspeaker generates the sound waves that test how acoustic perturbation affects the gas flame and b) A cut-away image of the high pressure combustion duct. Windows (far left and right) built into the apparatus enables monitoring of gas combustion.

Reproduced with permission from reference 1. Figure 1a and b © 2018 Elsevier

Soldiers marching lockstep across a bridge can cause the structure to collapse if the rhythm of their step matches the bridge’s natural vibration frequency. Combustion engineers must consider a similar effect when designing the gas turbines used

in electricity generation and aero-engines.

Just as soldiers’ feet can cause bridge sway to reach the point of destruction, a gas turbine can be damaged, or even explode, if heat and pressure fluctuations produced by the flame couple

with the acoustics of the combustion chamber. At a lesser degree, this‘thermoacoustic instability hampers efficient combustion, increasing noise and pollution emissions.

Predicting and preventing thermoacoustic instabilities remains

challenging for the design of a gas turbine. To improve the models used, Deanna Lacoste from KAUST's Clean Combustion Research Center and her colleagues have

measured the stability of gas flames at elevated pressure.

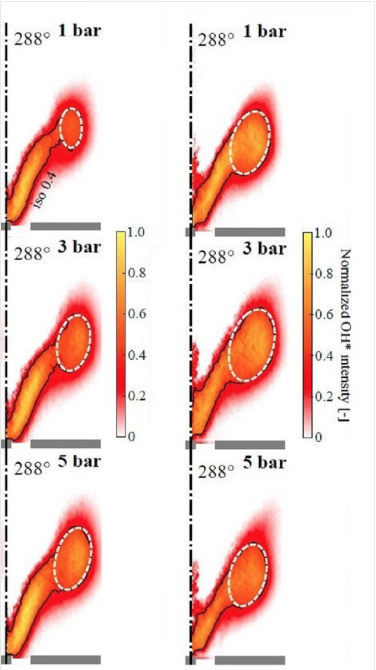

Lacoste, Di Sabatino and their colleagues systematically investigated the effect of pressure on methane and propane gas flames. “Our experiments show the FTF at atmospheric pressure is different to the FTF at elevated pressure,” says Di Sabatino.

For both methane and propane gas flames, pressure had a particularly strong effect when the loudspeaker produced acoustic perturbations of 176 Hz.

The size of the methane flame increased with pressure when the flame was subjected to acoustic perturbation of 176 Hz (left); for propane, the size of the flame peaked at 3 bars of pressure.

Reproduced with permission from reference 1. Modified from Figure 8 and 9 © 2018 Elsevier

Di Sabatino, F., Guiberti, T.F., Boyette, W.R., Roberts, W.L., Moeck, J.P. & Lacoste, D.A. Effect of pressure on the transfer functions of premixed methane and propane swirl flames. Combustion and Flame 193, 272-282

(2018).|

article