24 December, 2014

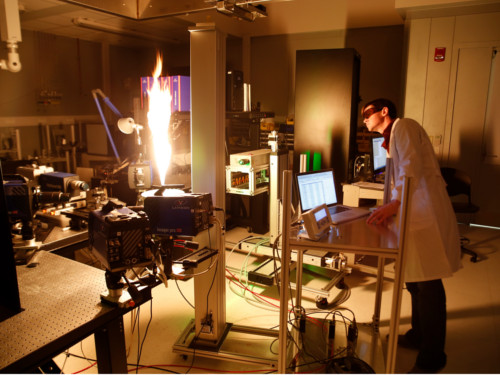

PhD student, Wesley Boyette, uses a four-camera system to examine a turbulent sooting flame, which is important in gas turbines. © Tunde Gaspar/KAUST

With the effect of climate change a major global challenge for householders, governments and industry, the drive to find cleaner, more efficient fuels and improve supporting technologies has never had stronger impetus. The Clean Combustion Research Center (CCRC) at King Abdullah University of Science and Technology (KAUST) draws on expertise from both academic and industrial sources to lead the way in new combustion technology design

“The CCRC at KAUST is unique for two key reasons,” says Aamir Farooq, faculty member at CCRC. “Firstly, the international team here provides us with a wide-ranging and diverse knowledge base. Secondly, we have access to many state-of-the-art facilities and technologies, such as high performance supercomputers and laboratories where we can simulate many different real-world combustion processes.”

Inside the laboratories of the CCRC, researchers are exploring a wide variety of combustion-related fields. At the crux of many projects are dynamic collaborations between CCRC and other KAUST centers, as well as with industry. Among its broad quest for discovery CCRC takes on inquiry-driven and application-driven research into future engines, chemical kinetics in fuels, computational fluid dynamics, and gas turbines for power generation, to name a few.

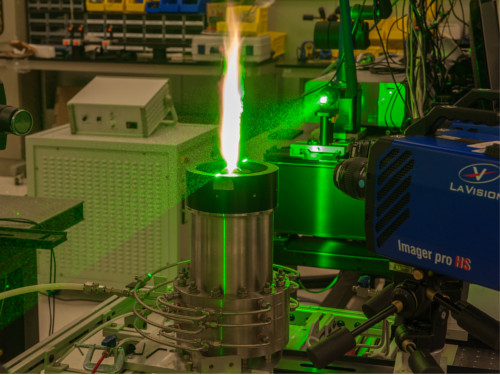

A green laser and camera system are used to do scattering measurements in a turbulent sooting flame.

© Tunde Gaspar/KAUST

“The CCRC is strong in exploring various combustion processes, including fuel oxidation, pollutant formation, and flame stability, in idealized conditions,” explains Farooq. “Measuring these processes in idealized environments allows us to validate predictive tools. These tools help us model combustion processes in realistic environments such as internal combustion engines.”

One example of simulation-based fuel design is the ‘Fuel Combustion for Next Generation Engines' program (FUELCOM), a collaborative project between CCRC and Saudi Aramco, Saudi Arabia’s state-owned oil company. Fuels used today will be unsuitable for the engines of the future; pollution mitigation and a drive for higher efficiency will demand fuel combustion in increasingly extreme conditions.

The FUELCOM program aims to develop new hydrocarbon-based fuels which can withstand these demands. For example, low temperature combustion engines would require fuels that produce low emissions and have improved ignition. Investigations into using low grade, low cost fuel such as naphtha (volatile liquid hydrocarbon fuel) and low energy, viscous fuels are also underway.

William Roberts, director of the CCRC, is working on a project investigating heavy fuel oil combustion for power generation, in collaboration with French multinational company Alstom and the Saudi Electric Company. Over the next five years, the researchers aim to resolve pollution and particulate issues related to the burning of heavy fuel oil. CCRC is designing new burners and plasma sources which can be used in on-site reforming to convert heavy fuel oils into higher quality, cleaner fuels for use in industrial boilers and furnaces.