Brand: Litron

Model: LDY-300

Simultaneous application of PIV and LIF techniques contributed to better understanding of turbulence–flame interaction, including flame extinction phenomena in turbulent non-premixed jet flames, low-swirl turbulent premixed flames, flame surface density, flame front curvature and turbulence statistics in lean premixed flames, flame-vortex interaction, strain rate in non-premixed jet flames, counter-gradient transport in premixed turbulent flames, partially-premixed counter-flow flames, and swirl-stabilized premixed flames.

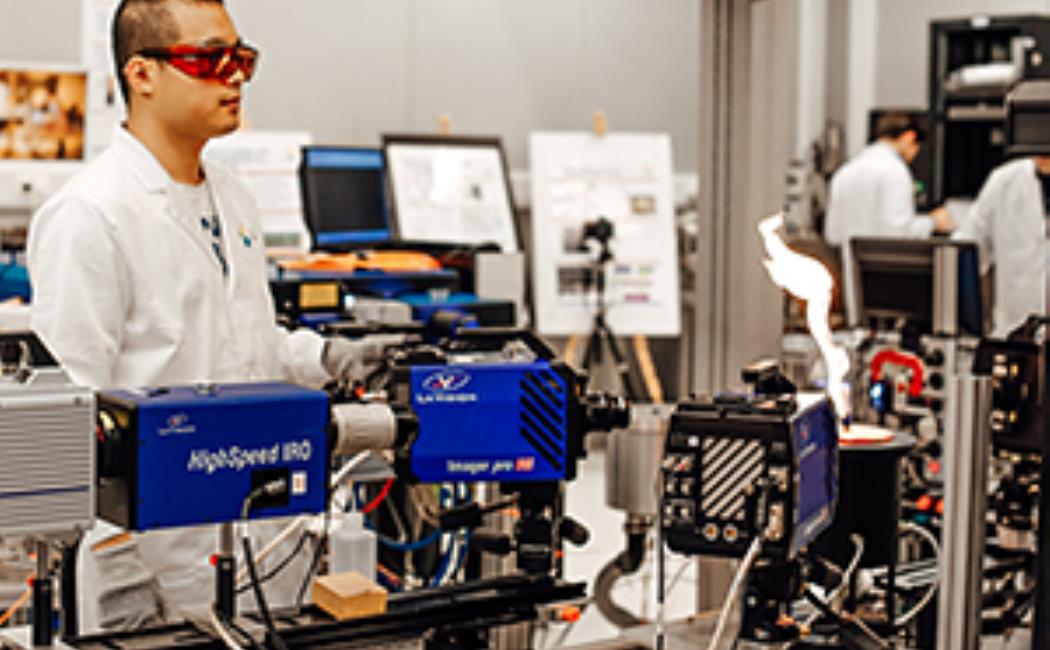

The SPIV system (La Vision, LDY 300) consisted of a high-repetition rate (up to 10 kHz) twin-cavity diode-pumped Nd:YLF laser (Litron, LDY304-PIV at 527 nm, 28 mJ/pulse, 5 ns pulse duration) and two CMOS cameras (La Vision, Imager Pro HS 4M with 2016×2016 pixels) coupled with a high speed controller. The laser output formed into a sheet of about 1 mm thickness and the height of about 90 mm using two-lens cylindrical telescope and time separation ranging from 10 to 200 µs are repeated at up to 10 kHz, producing 3D vector field.

TiO2 Seed particles with 0.18 µm nominal diameter are used for imaging purpose to measure the flow direction and speed of vectors inside the flame. the Seed levels are adjusted for accurate vector computation. The velocity vector fields were determined through multi-pass vector computation technique (using La Vision Davis 8.1 software) with interrogation region size of 24×24 pixels having 50% overlap, equivalent to a spatial resolution of 1.1×1.1 mm2.